Electric Drill

For drilling into common construction and shop materials.

Clear, practical product selection for industrial use. For availability, detailed specifications, and pricing, contact us with your requirements.

General-purpose tools for shop floors, maintenance teams, and project sites.

For drilling into common construction and shop materials.

For grinding, cutting, and surface preparation work.

For fastening and loosening bolts with controlled torque.

For heavy-duty drilling in masonry and tough substrates.

For clean cuts on metal sections and workshop components.

For controlled heating tasks in installation and maintenance.

For sharpening, deburring, and light grinding at the bench.

For straight cuts with stable handling in shop or site use.

For efficient fastening in assembly and routine work.

For breaking and removal tasks on concrete and masonry.

Core welding machines and supporting equipment for fabrication, site work, and repair tasks.

For manual metal arc welding with coated electrodes.

For continuous wire welding in fabrication and production work.

For precise welding on stainless steel and non‑ferrous materials.

For straight and profile cutting on conductive metals.

For workshop welding duties with stable output characteristics.

For direct current welding with consistent performance.

For reliable power transmission between machine and work area.

For secure electrode grip and safe work return connection.

For eye and face protection during arc and gas welding.

For supporting workpieces in practical welding positions.

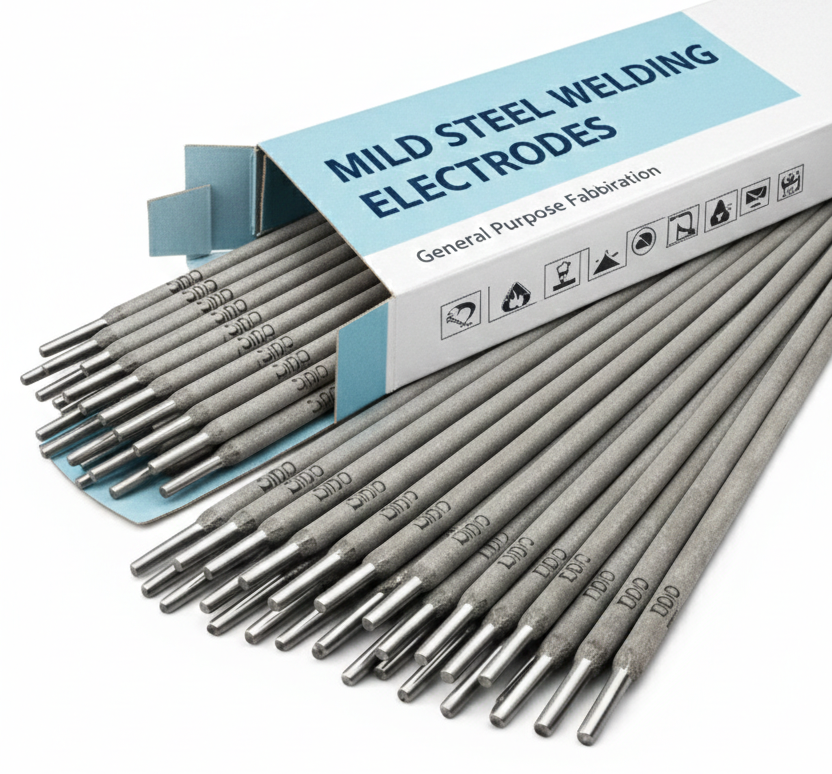

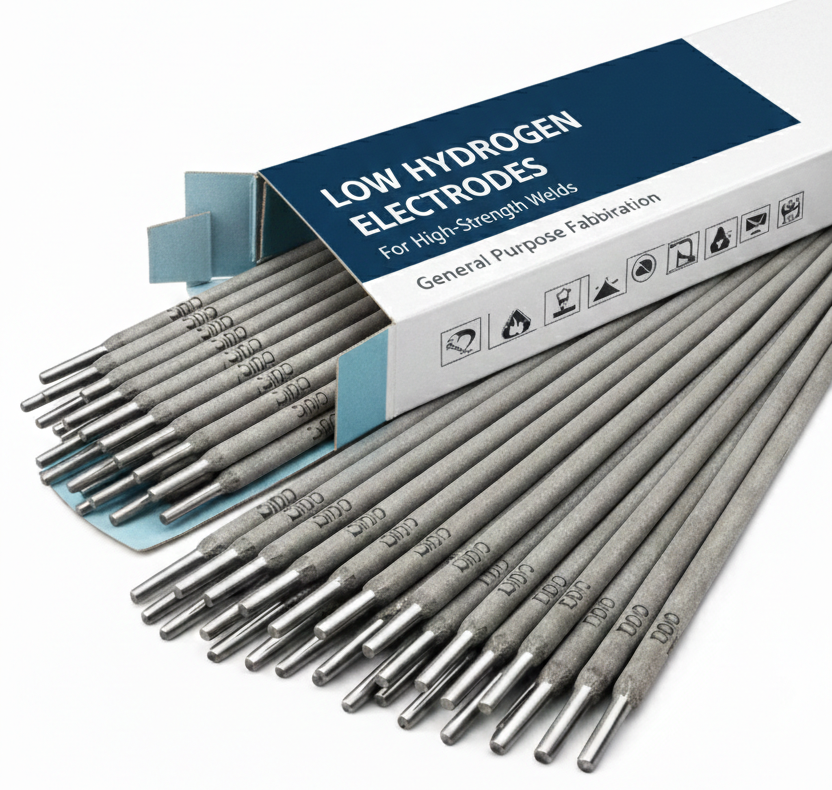

Welding electrodes for fabrication, repair, and general maintenance work.

For routine mild steel welding in shop and field work.

For welds requiring reduced cracking risk and stable results.

For stainless steel joining and corrosion-resistant repairs.

For cast iron repair work with controlled heat handling.

For wear-resistant buildup on exposed industrial parts.

For strong penetration in field conditions and pipe work.

For smooth arc control and consistent weld appearance.

For structural tasks requiring higher strength properties.

For specialized joining needs and dissimilar metal work.

A practical option for everyday welding and repairs.

All gases are imported and exported. No manufacturing.

Used for inerting, purging, and controlled environments.

Used in cutting, welding support, and process applications.

Used for shielding applications and process control.

Used as a shielding gas and for controlled atmospheres.